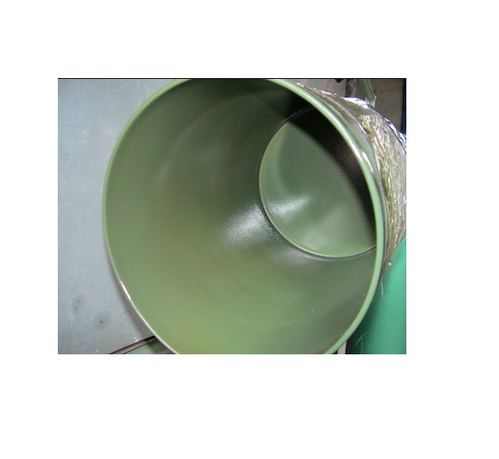

PTFE Coating / Xylon Coating

PFA Coating and PTFE Lining

Product Details:

| Metals | |

| Main Raw Material | PTFE |

The versatility of these coatings can solve the most difficult non-stick applications, provide excellent dielectric stability, reduce

1)

2) Low Coefficient of Friction: The coefficient of friction of Teflon® is generally in the range of 0.05 to 0.20, depending on the load, sliding speed, and particular Teflon® coating used.

3)

4) Heat Resistance: Teflon® industrial coatings can operate continuously at temperatures up to 260°C/500°F.

5) Unique Electrical Properties: Teflon® has high dielectric strength, low dissipation factor, and very high surface resistivity. By special techniques, it can even be made electroconductive enough to be used as an anti-static coating.

6) Cryogenic stability: Teflon® industrial coatings may be used at temperatures as low as -270°C/-454°F.

7) Chemical Resistance: Teflon® is normally unaffected by chemical environments.

Product Details:

| Application | Industrial Use |

| Industries Served | Semiconductor, Automotive |

| Types of Industrial Coatings | PTFE |

| Metals | Stainless Steel |

Halar Coating

Halar® ECTFE for Coatings Halar® ECTFE, a copolymer of ethylene and chlorotrifluoroethylene, is a semi-crystalline melt processable partially fluorinated polymer. Halar® ECTFE is particularly suitable for use as a coating material in protection and anti-corrosion applications thanks to its unique combination of properties. Key features · Very good chemical and thermal resistance · Optimum permeation resistance · Outstanding flame resistance · Very good surface characteristics · Surface smoothness · Purity Markets and Applications Typical applications served by Halar® ECTFE include those in contact with highly corrosive or ultrapure chemicals such as strong inorganic bases and strong mineral and oxidizing acids including: · Vessels · Reactors · Semiconductor chemical storage tanks and ductwork · Piping systems · Centrifuges · Agitators · Exhaust hoods · Filters · Electroplating equipment Pharma Chemical Industry High Purity Applications Pulp Paper

Xylan Coating

We are the recommended channel partners for application of a broad assortment of Xylan Coatings. These products are provided with a broad range of a properties which makes them ideal for a variety of applications like non-stick, corrosion resistance, etc. We cater to the following industries: automotive, aerospace, industrial, non-stick applications, fasteners and electronics. Offered product range is examined on defined parameters to make sure that these are as per the industry standards.