HCl Gas Generation Unit

With assistance from highly qualified and experienced professionals, we are occupied in offering a huge range of HCl Gas Generation Unit that is recognized for its indispensable features. Widely demanded in numerous industries, offered gas generation systems are designed using superior quality material and

HCl Gas Generation are available from 10 Kg.Hr to 300 Kg.Hr.

We offer

- HCL gas generation by Sulfuric Acid.

- HCl gas Generation with Distillation.

- HCl Gas Generation with Azeotropic Distillation with Calcium Chloride.

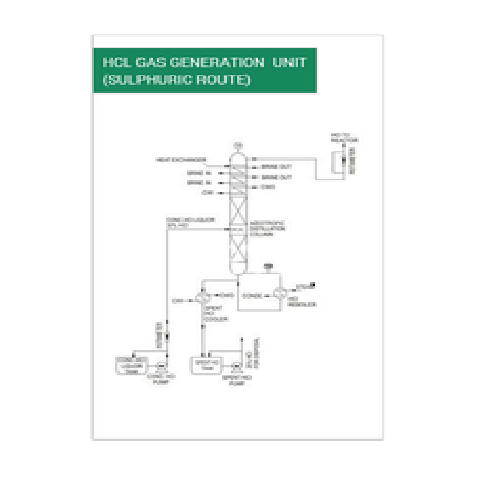

HCl Gas Generation Unit By Sulfuric Acid Route

Product Details:

| Minimum Order Quantity | 1 Set |

| Grade Standard | Analytical Grade, Bio-Tech Grade, Reagent Grade, Technical Grade |

| Usage | Industrial, Commerical |

‘Super Industrial Lining Pvt. Limited ‘ Supplies Various Dry HCl gas generation plant based on different capacities ranging from 5kg./hr. to 300 kg./hr.

Process Specifications:

- 30% HCl and 98% Sulphuric acid are fed to the Mixing Zone by the metering pump or from Overhead tank through Rotameter depending upon the customer requirement and site height availability.

- The HCl and H2SO4 feed are mixed prior to entry into the Reaction zone (Falling Film Tubular Heat Exchanger).

- The spent Sulphuric acid from the bottom of the Falling Film Tubular Exchanger is cooled in the Heat Exchanger, prior to discharge. The Liquid Cooler uses cooling water for cooling duty.

- The HCl gas generated in the Falling Film Tubular Heat Exchanger comes in contact with Conc. H2SO4 in the Drying Zone (Dehydrating packed column) Initial drying of the HCl gas takes place in this section. HCl gas from the top of the Dehydrating column is passed through Sulphuric Acid trap to minimize the moisture content in HCl Gas.

There are no moving parts in the entire system. The utility requirements, as well as floor space requirements for the Plant, are minimum.

All the wetted parts of the system are fabricated from corrosion resistant materials (glass/PTFE) for the process conditions envisaged.